With the accelerated deployment of the fifth generation of mobile communication technology (5G), 5G is getting closer and closer to our lives. The realization of 5G communication necessarily involves the upgrading of key devices. From core chips to radio frequency devices, from base stations to applications, higher requirements for key basic materials will be put forward. In the field of plastics, what requirements does 5G place on the industry, and what changes will it bring?

Higher technical requirements for basic materials

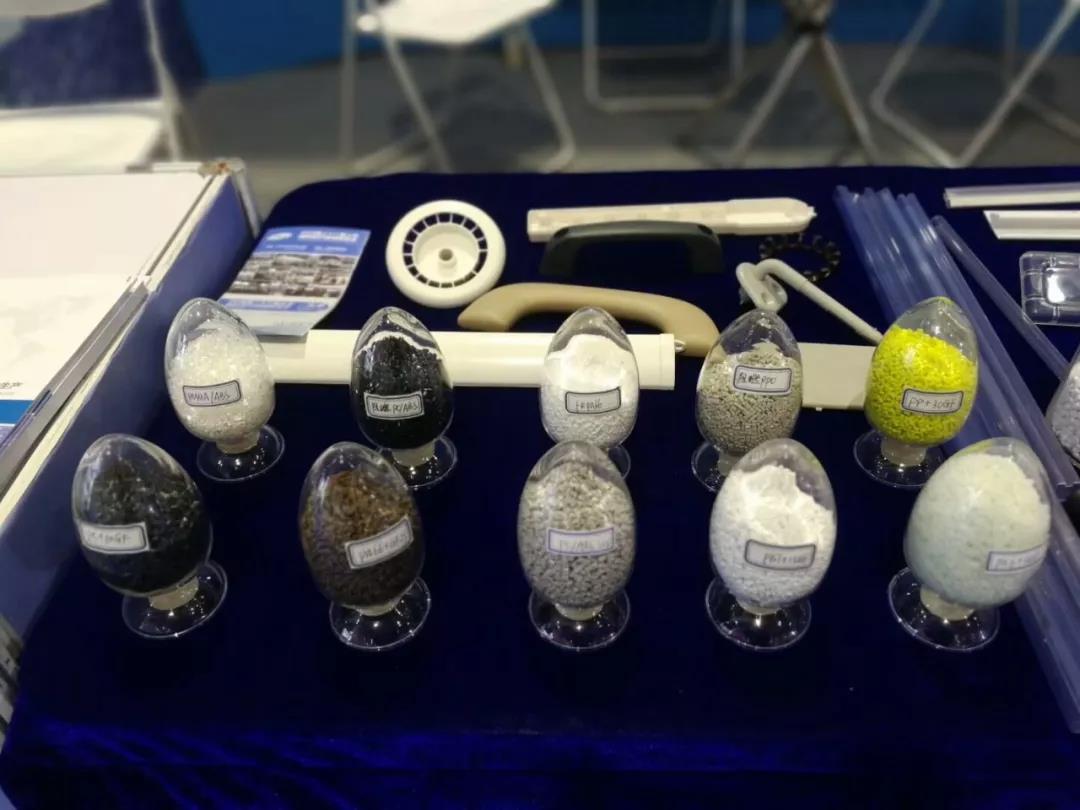

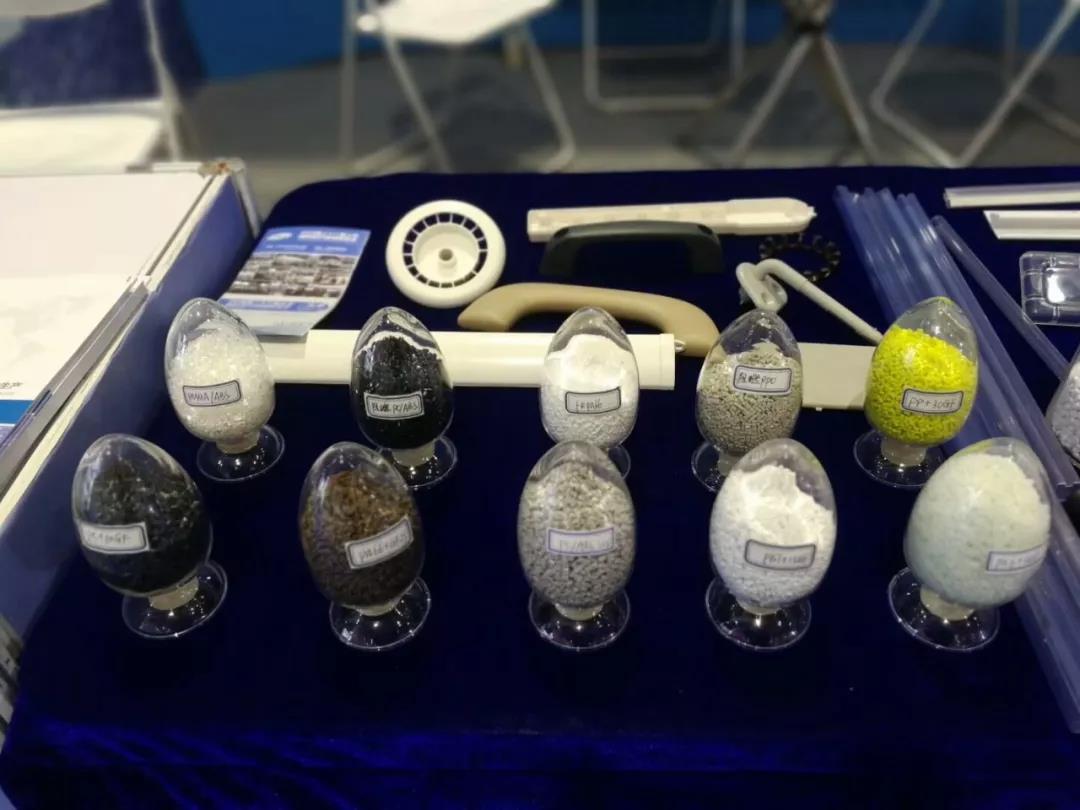

5G has the characteristics of a high-speed, low-latency, and interconnected network architecture. Plastics of a single type and nature are difficult to meet application requirements. Modified plastics are one of the basic raw materials necessary for 5G technology to achieve. Among them, the 5G communication method has higher requirements for the dielectric properties of modified plastics. The dielectric constant has a great influence on the signal transmission speed, signal delay, and signal loss of 5G communication millimeter waves. It is beneficial to improve the signal transmission speed, reduce signal delay, and reduce signal loss of smart terminals. Therefore, for developers of modified plastics, paying attention to and coordinating the dielectric properties of materials and seizing the development trend of 5G technology can prepare materials that meet the ecological wisdom of all things.

High requirements for mobile phone back cover materials

The massive MIMO technology used in 5G requires the addition of a dedicated antenna to the mobile phone, and the metal will shield and interfere with the signal. Therefore, the demetalization of the back cover of the mobile phone will be the general trend. At present, the material of the back cover of the mobile phone is changing from metal to glass and ceramic. And plastic, among which plastic is one of the most popular materials, but the ordinary injection molding + sprayed back cover and protective cover can not meet the requirements of the 5G era, the future trend is close to metal or glass in texture and experience At present, the IMT and back cover PC injection molding + coated plastic shell have made a qualitative leap in appearance and texture, and plastic-related companies still have a lot of room for improvement in the protective shell market.

Performance indicators include: aesthetics (visual and hand feel), abrasion resistance, drop resistance, heat dissipation, dielectric constant, and electromagnetic shielding effects (5G signal permeability). At present, there are several materials that have attracted much attention. The hard metal damage is the electromagnetic shielding effect. At the same time, the metal is conductive, and it is also an obstacle to the wireless charging function of the mobile phone. The weakness of plastics and composite materials is the poor wear resistance and heat dissipation performance, and the aesthetics. (Especially feel and texture) is also difficult to compare with other materials; glass as a whole has better comprehensive performance, only the drop resistance needs to be improved, and the heat dissipation performance is average; nano-zirconia ceramics have the best comprehensive performance, 6 properties The indicators perform better. The public is most worried about whether nano-zirconia ceramics are as resistant to falling as glass. In fact, as long as the quality of nano-zirconia powder raw materials passes, the toughness of nano-zirconia ceramics is beyond imagination.

Mass production feasibility indicators include: the availability of raw materials, the economics of investment in production lines, and the price advantage of single-chip finished products. The availability of raw materials determines whether this type of mobile phone backplane is feasible for mass production. At present, the production capacity of high-end nano-zirconia powder is very scarce in China. Without solving this problem, it is difficult for nano-zirconia ceramic mobile phone back plates to become the choice of mainstream brand mobile phones. The abundant supply of raw materials such as glass, plastic and composite materials has also led to fierce cost competition among manufacturers of mobile phone backplanes. In theory, controlling a scarce and suitable raw material and using it to mass-produce mobile phone backplanes is the optimal market strategy for 5G mobile phone backplane manufacturers.

The economics of investment in production lines determines the investment willingness of mobile phone backplane manufacturers. At present, the mainstream domestic supplier of ceramic mobile phone backplanes adopts the dry forming process. The huge investment in post-processing equipment has directly resulted in limited production capacity and poor economic feasibility of expanding the mass production scale. So far, it does not have a million pieces. Order ability for level orders. After experiencing a crazy competition in the investment of metal mobile phone backplane equipment three years ago, mature mobile phone backplane manufacturers no longer dare to ignore the economics of equipment investment.

The price advantage of a single piece of finished product determines the future market share of the material. Under sufficient market competition, the market prices of glass mobile phone backplanes (including 3D curved glass and 2.5D glass, 2D flat glass) and plastic mobile phone backplanes are almost transparent. When nano-ceramic mobile phone backplanes enter the high-end market, they need The market price of a single piece of finished product should be close to the price of the same grade of glass backplane; when other materials enter the low-end backplane market, the price of a single piece should be close to the same grade of plastic backplane.

In summary, modified plastics may become the trend of use.We have more than 28 years history of PVC mixture formulation development and granulation products, we have been providing high quality products and services to Southeast Asia, North America, Europe and other countries for many years. If you are interested, please contact us.