The bending deformation of PVC profiles is a common problem in the extrusion process. The reasons are: uneven discharge of the die; when the cooling is set, the material is not cooled enough, the amount of shrinkage is inconsistent; equipment and other factors.

The concentricity and level of the whole line of the extruder are the preconditions for solving the bending deformation of the PVC profile. Therefore, the concentricity and level of the extruder, the die, the setting die, the water tank, etc. should be corrected whenever the mold is changed. Among them, ensuring the uniform discharge of the die is the key to solve the bending of PVC profiles. Before starting the machine, the die should be carefully assembled, and the gaps of all parts should be consistent. If the die is found to be uneven when starting, it should be based on the bending deformation direction of the parison. Adjust the temperature of the die. If the adjustment is invalid, the plasticity of the material should be appropriately increased.

Auxiliary adjustment and adjustment of the vacuum and cooling system of the sizing die is a necessary means to solve the deformation of the PVC profile. The amount of cooling water on the side of the tensile stress should be added to the large-scale material; the mechanical offset center method is used to adjust, that is, while the production is being adjusted. The positioning bolt in the middle of the shaping die is reversely adjusted according to the bending direction of the profile (the method should be used with caution and the adjustment amount should not be too large). Paying attention to the maintenance of the mold is a good preventive measure. Pay close attention to the work quality of the mold, and maintain and maintain the mold at any time according to the actual situation.

By adopting the above measures, the bending deformation of the profile can be eliminated, and the extruder can be stably and normally produced with high quality PVC profiles.

Low temperature impact strength

The factors affecting the low-temperature impact strength of PVC profiles are formulation, profile cross-section structure, mold, plasticization degree and so on.

(1) Formula

At present, CPE is widely used as impact modifier. CPE with a chlorine content of 36% has the best modification effect on PVC. The dosage is generally 8-12 parts by mass, and the crystallinity and glass transition temperature are low. Flexibility and compatibility with PVC.

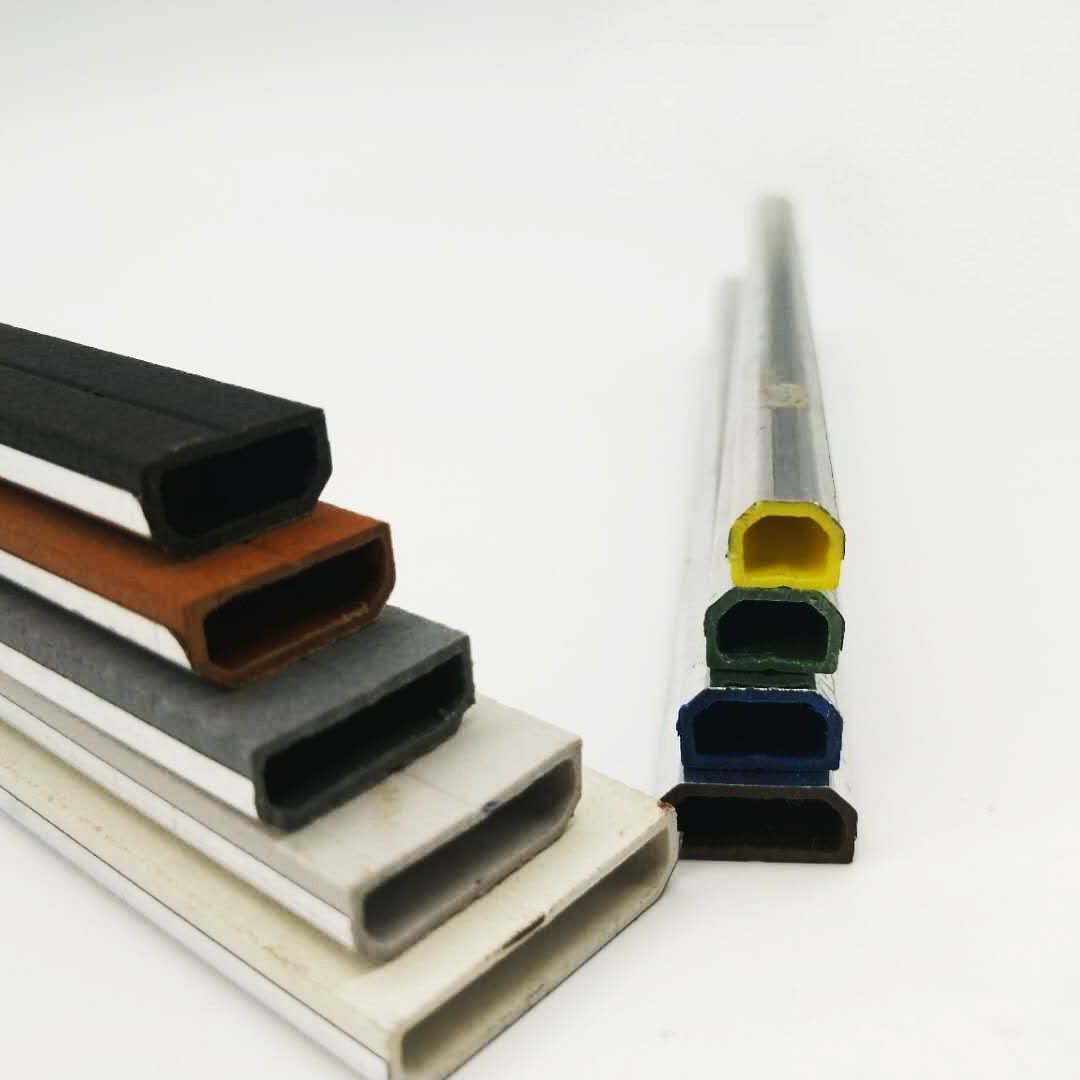

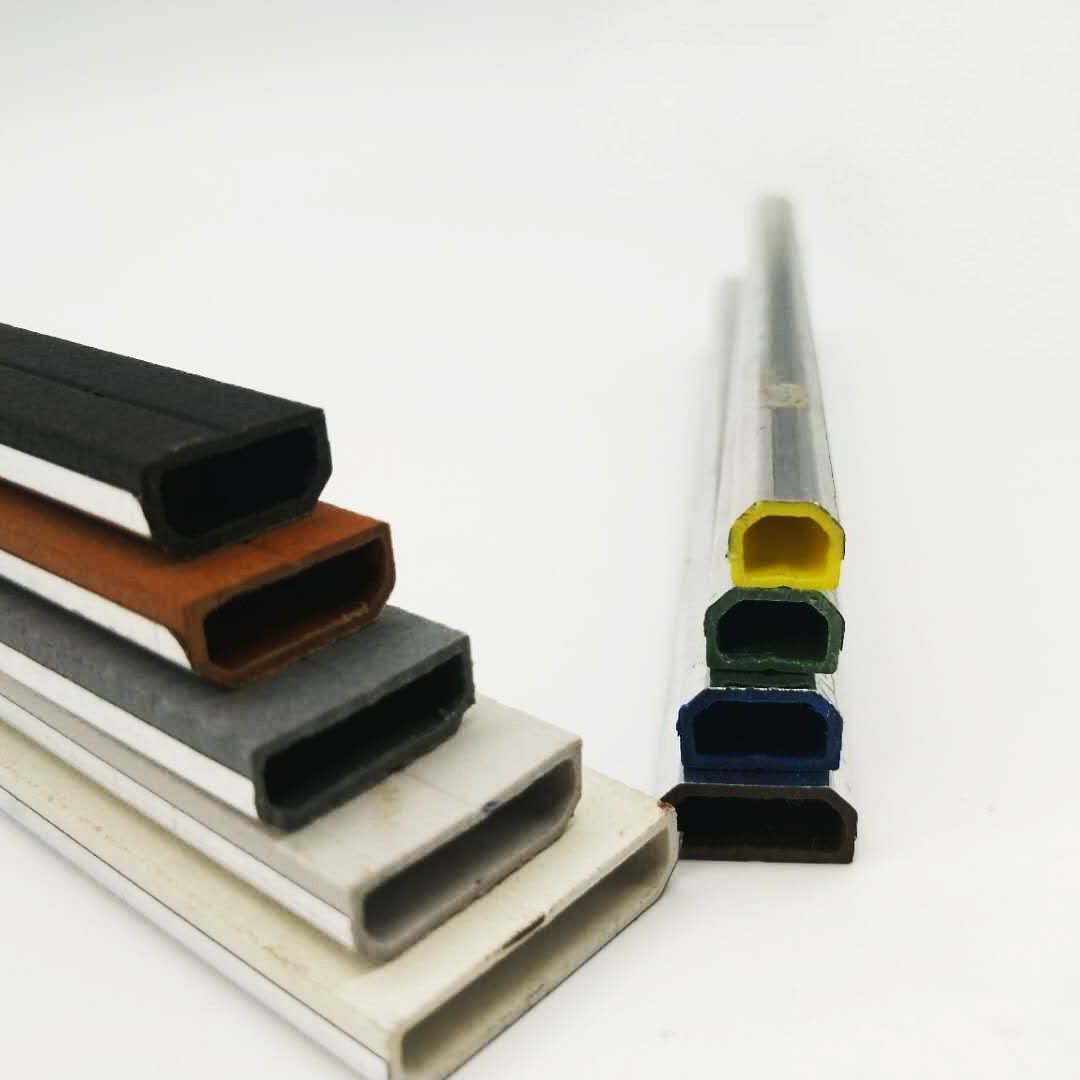

(2) Profile cross-section structure

High quality PVC profiles have a good cross-sectional structure. Under normal circumstances, the structure of the small section is better than that of the large section, and the position of the inner rib on the section is appropriate. Increasing the thickness of the inner ribs and adopting a circular arc transition at the joint between the inner rib and the wall contributes to the improvement of the low temperature impact strength.

(3) mold

The effect of the mold on the low-temperature impact strength is mainly reflected in the melt pressure and the stress control during cooling. Once the formulation is determined, the melt pressure is primarily related to the die. The profile from the die undergoes different cooling methods, resulting in different stress distributions. The low temperature impact strength of PVC profiles where stress is concentrated is poor. When the PVC profile is subjected to rapid cooling, it is easy to generate large stress. Therefore, the arrangement of the cooling water passage of the fixed mold is very critical. The water temperature is generally controlled at 14 ° C - 16 ° C. The slow cooling method is beneficial to improve the low temperature impact strength of the PVC profile.

Ensure the best condition of the mold, clean the mold regularly, avoid the impurities from clogging the die due to continuous production for a long time, resulting in reduced discharge, too thin support, affecting low temperature impact strength. Regular cleaning of the sizing die ensures sufficient sizing vacuum and water flow for the sizing die to ensure adequate cooling during profile production, reduce defects and reduce internal stress.

(4) Plasticization degree

A large number of research and test results show that the optimum value of low temperature impact strength of PVC profiles is obtained when the degree of plasticization is 60%-70%. Experience has shown that "high temperature and low speed" and "low temperature and high speed" can get the same degree of plasticization. However, low temperature and high rotation speed are preferred in production, because the heating power consumption can be reduced at low temperature, and the production efficiency can be improved at high speed, and the shearing action of the twin-screw extruder at high speed extrusion is obvious.