Insulating glass should be familiar to everyone. Insulating glass is a kind of building material with good heat insulation, sound insulation and beautiful appearance. The traditional insulating glass is prone to airtightness and watertight leakage after years of wind and sun. Condensation will occur at the edge of the glass; since most of the objects have the characteristics of thermal expansion and contraction, the expansion of the insulating glass will cause the glass to self-explosion due to the difference in expansion coefficient when the external temperature changes drastically.

Insulating glass spacers are an important part of the door and window system, which can effectively avoid these "hidden dangers" of insulating glass. The unique stainless steel surface greatly improves the airtightness and water tightness, and greatly reduces the leakage rate of the insulating glass. Since the warm edge strip has a very low heat conductivity, the condensation of the edge of the insulating glass can be greatly reduced and prevented. Mold growth, greatly extending the service life of insulating glass.

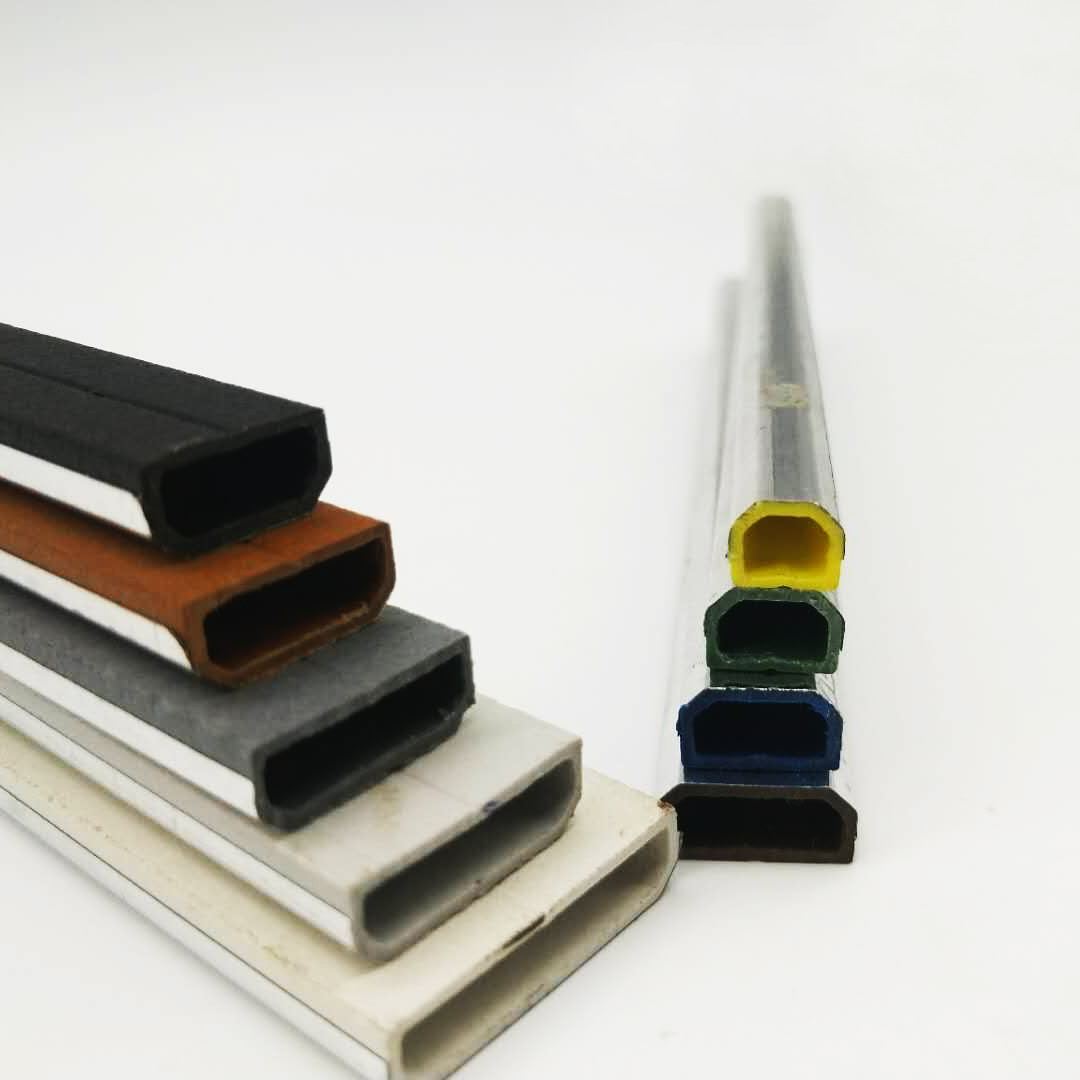

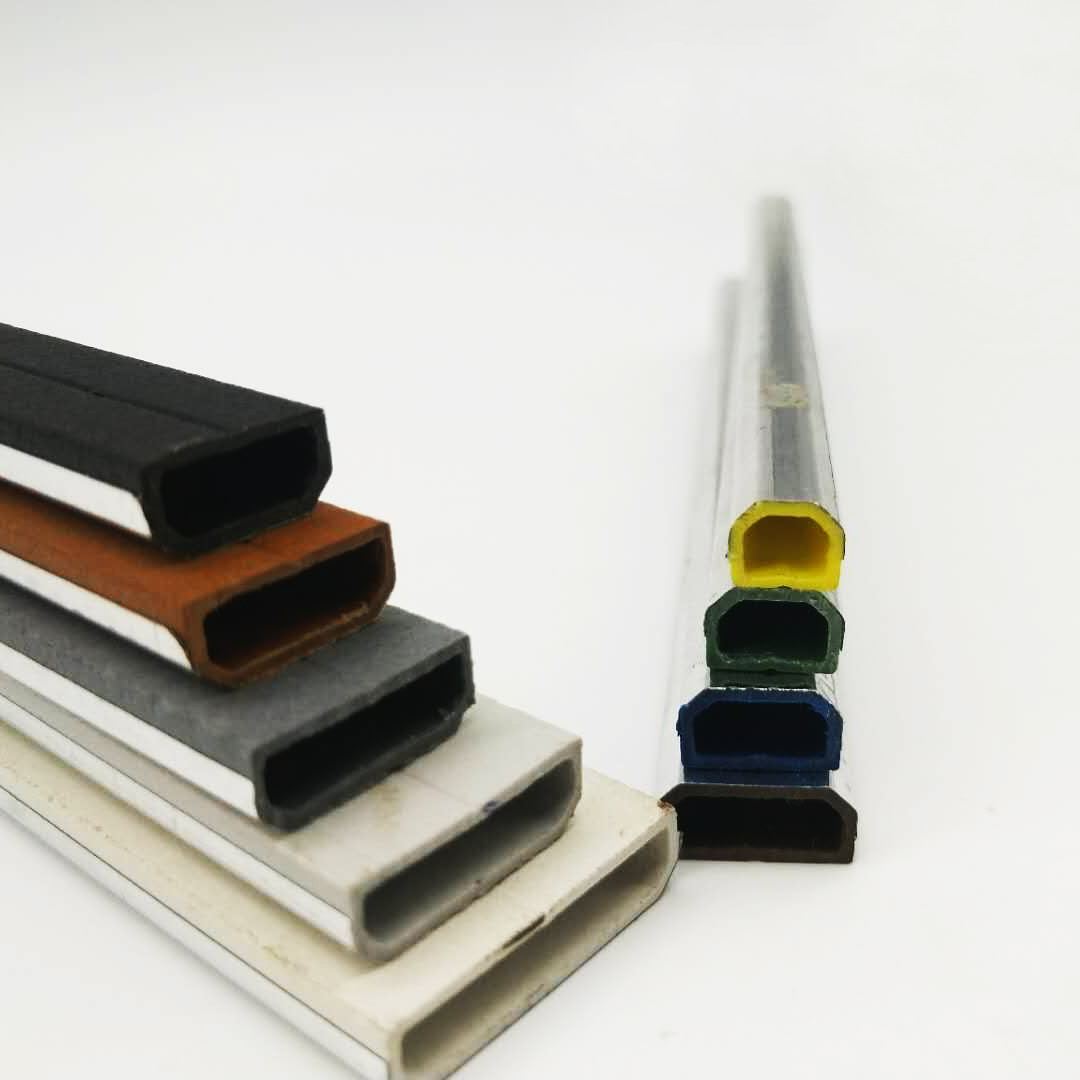

The polymer composite material (UPVC) warm edge spacer is composed of polymer composite material (UPVC) and 0.1mm wall thickness stainless steel, which is used to fill the molecular sieve, isolate the original piece of the insulating glass, and support the structural product. The expansion coefficient is 0.14, the expansion coefficient of stainless steel is 1, and the comprehensive coefficient is less than 1. It is the product that can be the closest to glass in the popular use of materials in the insulating glass industry, which greatly reduces the late risk caused by thermal expansion and contraction.

As we all know, there are many kinds of plastics. Let me tell you why you should choose UPVC warm edge strips.

In terms of characteristics: What is the difference between them?

1. Aging, weather resistance

PVC resists heat, oxygen, and light (ultraviolet light) to promote decomposition.

That is, anti-aging and anti-UV are better,

This is why the door and window profiles are made of PVC!

2. Cold resistance

The embrittlement temperature of PP is 35 degrees, the embrittlement temperature of PS is -30 degrees, the ABS is -40 degrees, the SBR is -55 degrees, and the embrittlement temperature of PVC can reach 60 degrees, so PVC is less likely to be caused by low temperature. Crisp damage.

3. Thermal conductivity

The thermal conductivity of PP is 0.21, the thermal conductivity of rigid PVC is 0.17, the soft PVC is 0.1, and the PC is 0.2 and the ABS is 0.25.

Whether it is hard PVC or soft PVC thermal conductivity is lower than similar products, so PVC is more suitable for warm edge strips!

4. Flame retardant

All countries have established mandatory flame retardant standards for building materials and so on, and strictly stipulate the required flame retardant grades for various products.

UPVC has a flame retardant oxygen index of 36, which is a difficult to burn grade.

Among them, PC is 24.9 is flammable, other PP, PE and PS are less than 20, which is flammable. In terms of environmental protection, other plastics such as PP are likely to cause secondary pollution.

Comparison of PVC compared to PP is more suitable for warm edge strips than PP.

Our company specializes in the production of PVC granules and modified PVC granules for up to 30 years to meet the needs of our customers. If you are interested, please contact us.